Our Roots

in Robotics

Our DNA comes from a background in Robotics developing robotics control software for companies all over the world.

AI Robotics

We were one of the first companies to use Inverse Kinematics (IK) to allow precise control over the End Effector on a Robot Arm, and since this our fascination has only grown and developed into the manufacture of applications such as precision spraying for weed control, fruit picking and harvesting.

We can apply our robotics control software to almost any application you can imagine and also add Artificial Intelligence (AI) to allow selective and reliable control.

Use Cases

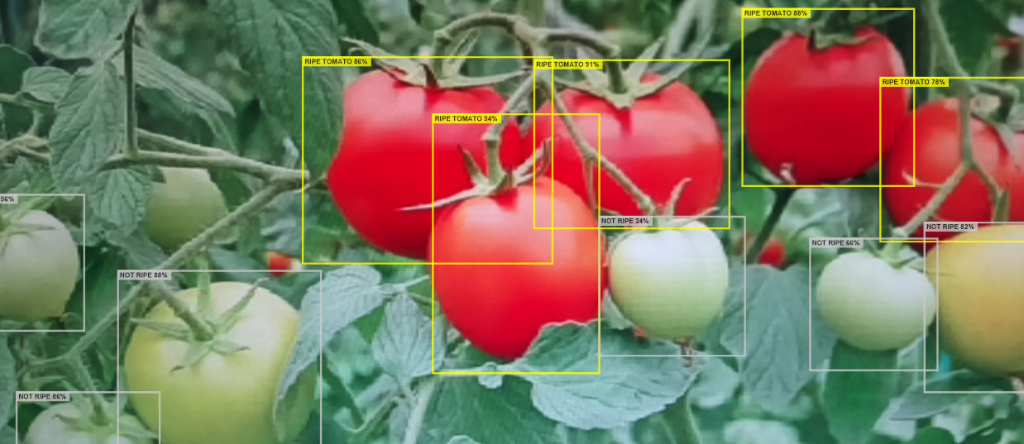

Fruit Picking Robot

One of the latest technological advancements in the fruit-picking and allotment field is robotic AI companions that assist and provide efficient help with the picking of fruits and vegetables. These robots can increase productivity and decrease labour costs while in no way threatening the jobs of the other pickers.

Our AI technology collects data about the location of fruit and vegetables by scanning the immediate surroundings of the plant leaves. A mobile platform then navigates and serves as a support for the mechanical picking arm, which uses a stereo vision camera to make location-based specifications using ‘visual data’ in order to know which strawberries to pick.

New technology is being refined every day in order to ensure 100% safety and efficiency, and with the rapid development that the Cavonix team are skilled in, the AI cultivators are to be made available in the not-too-distant future.

Weed Spraying Robot

Targeting the application of any and all fertilisers, herbicides, fungicides and insecticides autonomously incites a streamlined, sustainable process for spraying of pesticides and fertilisers on farms. Our innovative spraying application ecologically combats and destroys weeds and treats produce to keep farms and allotments healthy and thriving.

95% of weeds can be easily destroyed using the weed spraying robotic AI companion, also decreasing 70% of product wastage by calculating precisely how much is needed, and where it is to be distributed.

Soil Sampling Robot

Sampling soil manually can lead to making mistakes and causing errors as high as 20%. This can lead to major overestimations for expenses and wastage of products for markers who believe they need more or less product than they really do.

In order to make this process flow efficiently and reduce errors steadfastly, the soil needs to be sampled from the same spot season to season, this allows identification of the soil’s evolution and helps to build a data report that can massively benefit farmers who will know when volumes of products increase and decrease, and give annual overviews of any changes flagged. Autonomous soil samplers maximise this process and keep farmers’ time and effort free for other important practices.

Hardware

Our hardware has been refined and and tested to ensure the highest levels of safety and precision. The hardware we provide is second to none.

CAVDAQ

CAVSense

CAVGPS

Software

Our software is second to none, our exclusive CAVTech systems are tried and tested to provide you with the most efficient technologies.